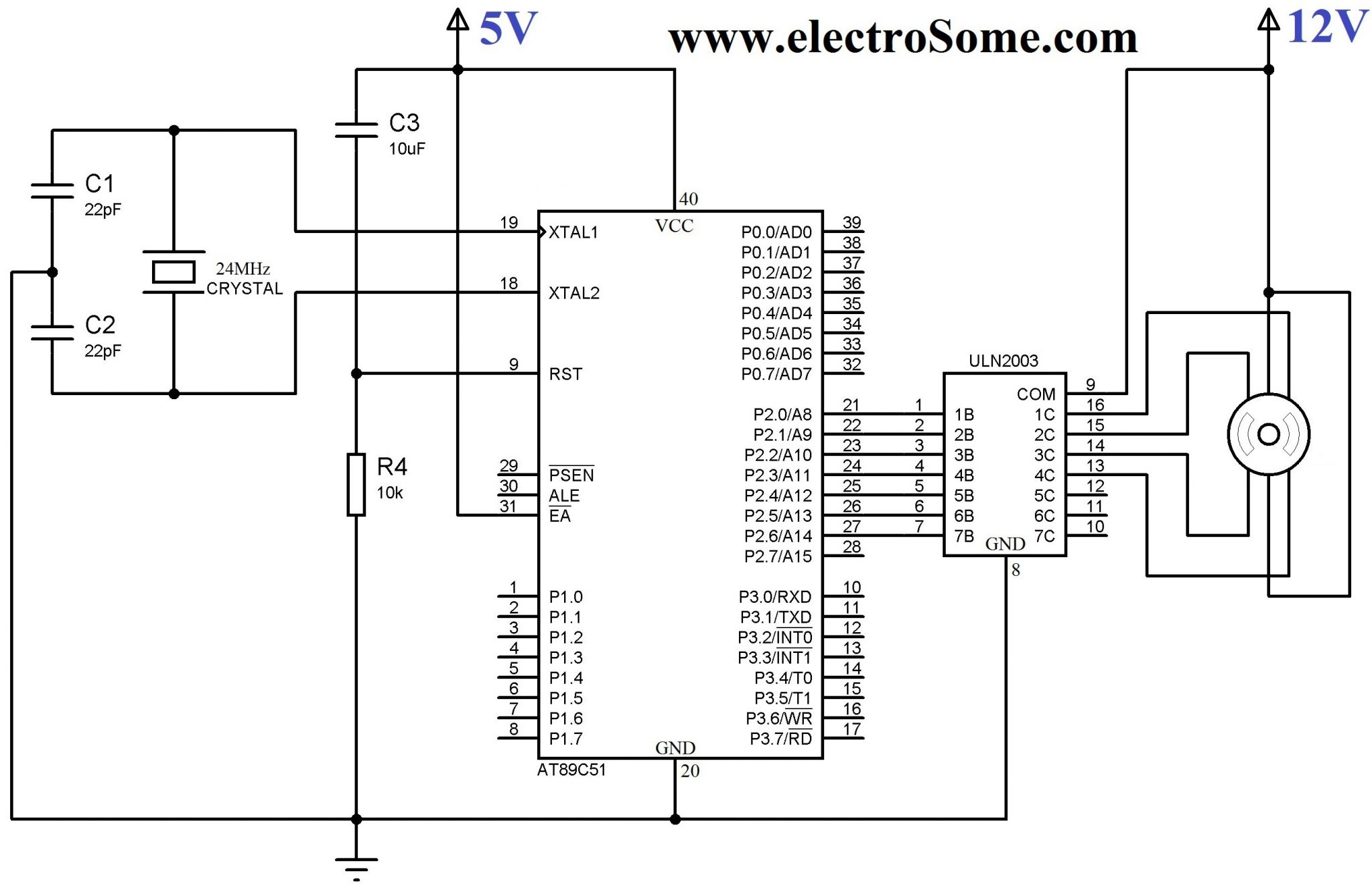

Here is a simple example for interfacing Unipolar stepping motor with assembly code. Instead of using a dedicated stepper motor driver IC like very popular PIC16F with were used.

How Bipolar Stepper Motors Work

Just 4 I/O Pins are required to drive each coil of the motor. By energizing each coil in a particular sequence you can control the speed and direction of the motor. 4 lower bits of PORTC are used for controlling the, triple nested loop is used to delay winding switching to about 200ms. Decrease the delay for more speed but not too much, otherwise your motor will “stall”. More advanced code should be available in a few weeks. I’m planning to expand a design by adding solar tracking capabilities using stepping motors, so this small project is a good beginning for testing various designs and interfacing techniques. 4 Unipolar step motors were tested (5 leads), see attached schematic and pin out for each motor, these motors were dismantled from old printers and scanners. So now we’ll need to identify the individual coils and common connection of the motor.

I have tried to run a hard disk motor with a pic 16f84a and a ULN2003 The motor is rotating but at a very slow rpm. Can anyone please tell.With Instructables you can share what you make with the world, and tap into an ever-growing community of creative experts. T8 Torx driver.Hard Disk Motor Driver (TDA5144AT breakout) from hotchk155. Jul 22, 2016 - To control the bipolar stepper motor we need two H-bridge circuits and for that L293D motor driver chip is used, this cheap chip can work as a dual H-bridge drivers. IR Remote controlled cd-rom bipolar stepper motor using PIC16F877A and L293D CCS PIC C. L293D Half H-Bridge motor driver pinout.

Use your to measure resistance between pairs of wires, it should be around 120 Ohm. The terminal with half of measured resistance is a common wire, connect it to positive voltage 5-12V depending on the motor.For identifying each coil there are a lot of techniques available, however I’ve used PIC to help me to find out the winding and connect them correctly. As explained above PIC will repeatedly send “1” to each coil according to its number. At this point you know were common wire is and it’s already should be connected to a positive voltage. Take one of the wires and assume that it’s Coil 4 and connect it to Coil 4 output.

Now you can use your fingers to feel the small movements every pulse and its direction. Take additional wire and connect it for example to Coil2 output, feel the direction of the movement. If it’s a correct wire the direction will be the same and the duration will increase with each attached wire till you have assembled them in correct order. At this point you can slightly decrease the switching delay to get continues rotation.

I’ve used this method on 4 motors and managed to find the correct winding in 15 minutes. First step motor is Mitsumi M42SP-4NP.Common – Red,W4 – Yellow,W3 – Orange,W2 – Black,W1 – Brown.

Next is PM35S-048-ZTP8 Minebea Electronics. Common – Red,W4 – Brown,W3 – Yellow,W2 – Black,W1 – Orange. Now for Canon QH4-4115 Stepper Motor. Common – Black,W4 – Red,W3 – White,W2 – Yellow,W1 – Brown. The last motor had no marking, but its wires configuration was the simplest among all tested steppers.

If you hold it looking at the back of the motor the first wire from the left is a common followed by W1,W2,W3,W4. That’s it for now. I’ve also found 2 Bipolar motors with 4 leads we’ll see if a simple PIC interface can be built and published. For more detail.

Commonly people use Darlington Array to control stepper motors such as ULN2003 or ULN2004. Here I want to show you how to use L298N Dual Motor Driver to drive a 4-wire bi-polar stepper motor. Well, it may be more expensive than a Darlington Array Chip so consider this as an 'option'. The reason I am working with this test is:.

Unipolar Vs Bipolar Stepper Motors

There was a comment on my questioning why I did not use a driver module or at least transistors to drive the 5V bi-polar stepper motor. It was because I couldn't find a Darlington Array Chip in town. I only had one L298N motor driver which I saved for my.

Thank God now I have 3 Keyes L298N motor drivers for testing (^^ ). I also read some people out there asking how to do this, they had the same problem with me, didn't own a Darlington Array chip but had a L298N driver in hand. So I search on the net to learn more about a stepper motor, particularly a 4-wire bi-polar stepper motor which I used in my project. It is a mini 5V stepper motor which can be found in a floppy disk drive. Internal diagram of a 4-wire stepper motor can be drawn like picture number one above. While picture number two shows us the internal working of a stepper motor to make it moves clockwise or counter clockwise.

All we have to do is energized the coils in correct orders. From the Movement Diagram above: Clockwise Degree Y X Y X 225 0 0 1 1 315 0 1 1 0 45 1 1 0 0 135 1 0 0 1 Counter Clockwise Degree Y X Y X 225 0 0 1 1 135 1 0 0 1 45 1 1 0 0 315 0 1 1 0 How do we figure out which wires in pair (X and X; Y and Y)? Because we want to SOURCE or SINK the coils to produce desired magnetic field to move the motor. Use a multimeter and set it to Ohm Meter, we are measuring the resistance between cables.

When I measure pin 1 and pin 3 it reads 12.6 ohm. So is it when I measure pin 2 and pin 4. There is a resistance when the pins are connected. We can also set the multimeter to 'continuity check'. When I measure pin 1 and pin 2 it shows '1' on the left side which means 'out-of-range'. The same thing happens when I measure pin 2 and pin 3.

That means they are not connected. You can try visit this page for more detail information about. It has some GIF animations and a complete table of stepper degree and state of pins to make you understand better. You could, but I've heard rumors of possible problems of back-feeding the +5V, raising havoc with the switching between USB & on-board regulated +5V.

I would never, however, feed the +5V pin of the arduino to the LM298N alone, rather, a separate +5V supply should be used. This causes the Arduino's regulator chip to overload, and causes the AVR itself to brown-out with lack of power. Never power anything stronger than 2 RC servos off the +5 pin! I've run most of my projects off a +12V output from a modified ATX supply, BUT. Fed the power through two regulators in series, from +12 to the input of a 7809 (+9V regulator), and the output from the 7809 to the input of a separate 7805 (+5v regulator), creating a +9V rail (Arduino main supply) and +5V rail (servo, other logic requiring higher amperage.) all common GND. I keep running into steppers which are in the 1.0 to 5-Ohm range, which leads me to believe they're more of the 3V & 5V coils, and feeding +12V to them would fry them. You can alter the L298N, by removing the jumper that send VMs (+12V, Motor Supply), and run a jumper from the VMs terminal, and put it in with the +5V terminal, with the wire from the external 7805.

This applies +5V to both the logic & Motor Supply sides of the L298N. (also, if your motors are in the 15-36V Range, Remove this jumper!! Anything higher than 15V will Cook the onboard regulator! And simply supply a separate +5 Logic supply.) 1 year ago.